How To Achieve Reliable Coding With Minimal Effort: The New Linx 8900 CIJ Coder

Maintaining reliable coding is essential for businesses, as line stoppages and unplanned downtime can really get in the way of meeting production targets. The new Linx 8900 printer has been designed for maximum reliability while being simple to set up and operate. Read on to find out more about how our latest continuous inkjet coder can give you a simple way to achieve the production line uptime you require.

Reliable production in all environments

Our customers use our coders in a range of production environments, which is why we’ve designed the Linx 8900 to be rugged enough to perform well in many different situations. The unit features a new stainless steel enclosure rated at IP55, ensuring its suitability for washdown environments. Meanwhile, the unit’s Temperature Auto Adjust function ensures code quality is maintained through various temperature ranges on your production line. These features ensure accurate, reliable coding you can rely on in a range of production environments.

Reduce coding errors

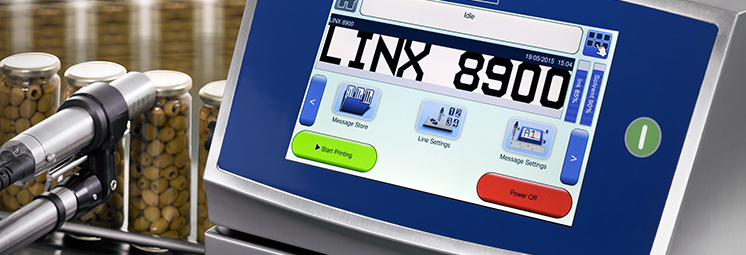

A major factor that can support reliable coding is a printer with an intuitive user interface, for quick and error-free message setups. As with other Linx printers, the Linx 8900 features an industry leading, easy to use interface, featuring the largest touchscreen we’ve ever built into a coder.

The easy to use interface has been purposely designed to reduce errors when setting up messages, thanks to on-screen prompts during message set-up, avoiding costly operator error. Furthermore, messages and multiple line-settings can be stored and retrieved within the system, further avoiding coding errors and speeding up set-up times.

Error-free fluid refills

But it’s not just the user interface that has been designed to reduce errors – the unit itself has also been built around avoiding errors during the fluid refill process. An 8-hour fluid warning system gives you notice to plan refills around your schedule, helping you meet production targets. The refill process itself is quick and simple. A unique, one-touch opening and closing mechanism means fluids can be replaced with no tools, and simply slot into place. Furthermore, the solvent cartridge is twice the size of the ink cartridge. Not only does this minimise the number of refills – because solvent is used more than ink – it also means it’s impossible to insert cartridges in the wrong slot. Furthermore, there are no exposed parts during the ink refill process, meaning no damage can be done to the unit, ensuring robust operation.

Reliable printing

Not only have solvent refills been minimised with the Linx 8900, so has printhead cleaning. Our industry-leading printhead includes an Autoflush system which ensures that manual printhead cleaning is reduced, with greatly reduced solvent use and quick, clean starts every time. The printhead typically only needs to be cleaned once every three months, thanks to its completely sealed unit which ensures reliable operation, even in harsh environments.

Perfect starts, first time

The Linx 8900 features a unique holiday shutdown mode, which is designed specifically for reliable start-ups even after prolonged shutdown periods. At the single press of a button, the printer is cleaned and ready to print, without any complicated manual draining, cleaning or setup procedures when the unit is required next. This ensures coding is legible and reliable even after extended shut downs, for example over the Christmas period.

Wrapping up

Thanks to its unique features and innovations, reliable coding just got easier with the Linx 8900.

Find out more about the Linx 8900’s technical specifications here, or contact us using the form on the right for a free quote.

|