Drinks manufacturers and packagers around the world are increasingly using stand-up pouches in their packaging for awide range of products, including mineral water, non-carbonated soft drinks and wine. While currently there are some limitations on the types of beverages that can be safely stored within pouches - for example carbonated soft drinks – new uses are being found all the time, for example in the last four years the sale of cocktail mix in stand-up pouches have grown from zero to 300 million units per year. Worldwide, the demand for pouches is expected to rise 6.2% each year to reach $37.3 billion in 2018, according to research by The Freedonia Group, with growth in Western Europe, the US, while the fastest growth is expected in China and other developing nations, meaning there are opportunities not just for UK brands, but export brands too.

But what are the reasons for this growth? A major reason is the perceived value for consumers. The Freedonia Group reports that consumers prefer the aesthetics of a stand-up pouch, as well as other features not found on certain other types of beverage packaging, such as spouts or handles.

How do Packagers and Beverage Manufacturers Benefit from Stand-Up Pouches?

Consumers are not the only ones who benefit from the growing use of stand-up pouches in the drinks industry – there are countless advantages for packagers and manufacturers. Firstly, pouch packaging weighs a great deal less than rigid packaging types, such as cans or bottles, using less material to hold equivalent volumes of liquid. The primary benefit of this is lower shipping cost, thanks to reduced weight per unit and the ability to fit more units in the same space.

Consumers are now more than ever aware of the ethical and environmental impact of goods and services, meaning the environmental benefits of stand-up pouches are a great way for brands to differentiate themselves and showcase their environmental responsibility.

On top of this, pouches allow much greater freedom for beverage brands to ensure their products stand out on store shelves. Instead of conforming to standard sizes and shapes, beverage manufacturers can now tailor their packaging to unique shapes, styles and designs, as well as the ability to print very vivid and clear designs onto pouches, providing greater possibilities for brand recognition and differentiation from competitors.

Stand-up pouches can also make a real difference on the shop floor, thanks to the greater possibility for creativity in merchandising. Bottles generally must be presented to the consumer on a shelf, while beverages in pouches may also be designed to be hung from pegs, allowing for more eye catching and unusual promotional stands in-store, which may improve sales.

Will Your Coding Solution Work With Pouches?

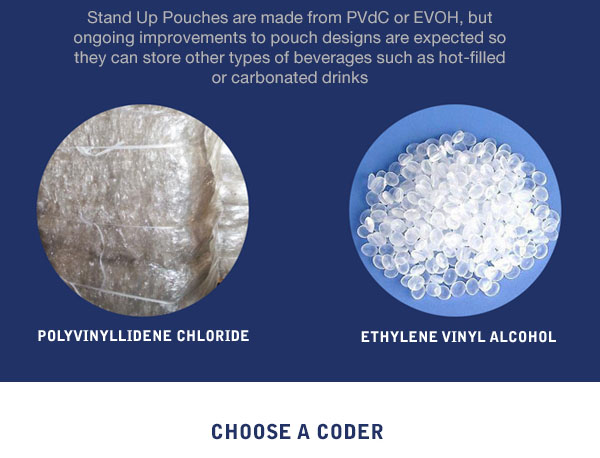

Currently, stand-up pouches may be made from flexible PVdC (polyvinylidene chloride) coated films, or EVOH (Ethylene vinyl alcohol), which is a cheaper solution. As the market for pouches grow, ongoing improvements are expected to be made on the barrier film substrates. For example, at present carbonated beverages cannot be stored in pouches due to escaping gasses. Similarly, pouches cannot be used for certain products that are hot-filled, but with improvements in heat tolerance, this will no longer be a limitation.

As a result of these changes, if you are looking to use stand-up pouches, it’s essential to ensure your coding solution can keep up with the developments in materials. Will your current printer still code effectively when the materials change?

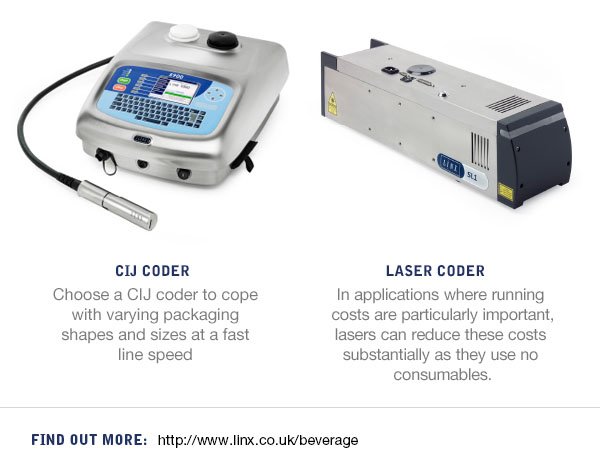

A non-contact printer such as a Continuous Ink Jet (CIJ) coder is the best solution for pouches, as it copes best with varying pack shapes and sizes whilst keeping up with your line speed. If your company packages a wide range of products, you’d benefit from a coding solution that can code onto several different packaging materials without rubbing off during production or end use. Using the correct ink also plays an important part here in ensuring coding does not rub off. Linx Black PE Ink 1130 for Linx CIJ printers is recommended in this instance as an all-round plastic adherent ink, meeting Swiss Ordinance 817.023.21 which also makes it suitable for food packaging applications.

An alternative non-contact coding solution is laser technology which is able to code onto most plastics. In applications where running costs are particularly important, lasers can reduce these costs substantially as they use no consumables.

Wrapping Up

Stand-up pouches are a fast growing trend in beverage packaging, with numerous features and benefits for consumers and brands alike. But in order to take advantage of this popular style of packaging, be sure to check that your coding solution is able to operate successfully on your products.

Discover more about printing and coding products on beverage packaging here.