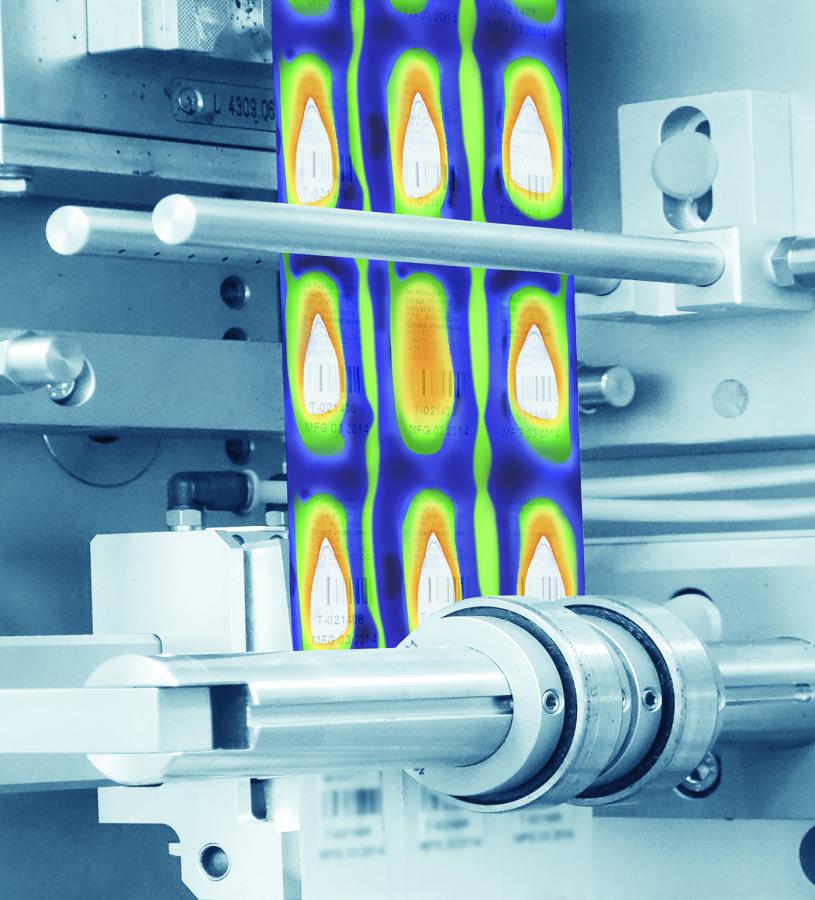

The Sachet Full Monitoring (SFM) Inspection Device utilizes thermal imaging technology – a non-invasive inspection technique that DIR Technologies formally introduced to the pharmaceutical industry earlier this year – to abandon random, inexact product sampling, providing a more accurate and less destructive testing process. To achieve this, the SFM Inspection Device takes advantage of heat developed during the sachet/pouch sealing process, allowing for completely passive testing that in no way interferes with individual products or the overall production process.

For all its technological advancement, the SFM Inspection Device is compact and easy to operate, providing intuitive user instructions and straightforward steps to incorporate the module into any existing sachet or pouch line. In addition, the SFM Inspection Device is available as an integrated option in MEDISEAL sachet machines.

Sachets and pouches are widely used in pharmaceutical and cosmetics products and, traditionally, checkweighing machines are used to verify that these packages are filled properly. However, this equipment tends to be bulky, cumbersome and expensive and, given their test-by-sampling nature, may provide insufficient levels of accuracy. This inexact inspection becomes especially tenuous in circumstances where, for example, sachets must contain an accurate unit-dose of medicine, or in cases where the weight of the content is smaller than the weight of the laminate itself.