Induction Integrity Verification System

What is it?

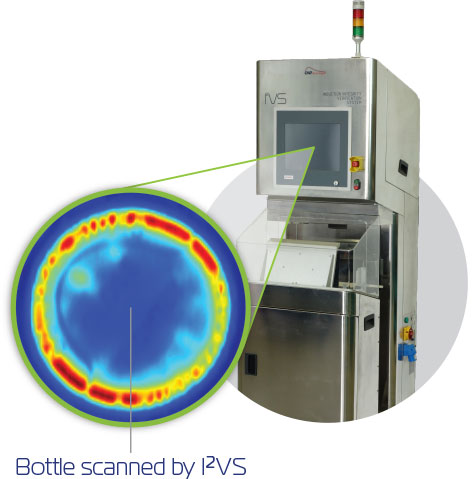

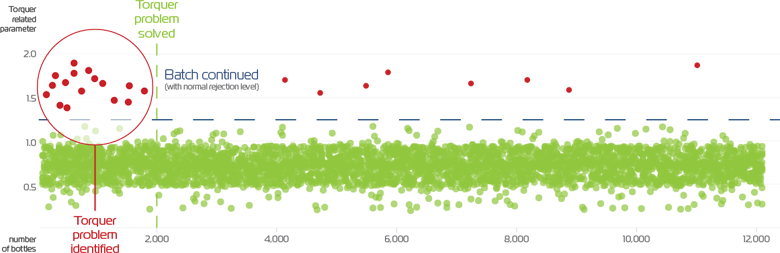

DIR’s I2VS is the first in industry 100% in-line inspection system for induction sealed bottles and jars that is non-intrusive and does not result in production slowdown. A quantum leap from sampling to monitoring every single package – the system goes a step further to provide process control by indicating not only if an issue occurs, but what caused it, giving the opportunity to amend in real time.

How does it work?

The I2VS combines high end thermal imaging normally used in the defense industry with sophisticated analysis algorithms and proprietary IP to provide real time integrity monitoring of every single bottle on the packaging line – at the speed of the machine throughput. Inspection is “hands off”, non-invasive and non-destructive. Nothing is projected at the product; the I2VS reads and analyzes the inherent heat signature of the cap’s liner (which is amplified directly after induction). The I2VS is compatible with most bottle and caps sizes and types and can be easily integrated in to almost any packaging line.

Why do I need I2VS?

• Ultimate quality assurance of primary packaging induction sealing – 100% inspection

• Unprecedented process control – Discover and fix potential problems in real time

• Fast – No slow-down of the packaging line

• Tamper evidence integrity verification

• Detects when the cap is not fully closed, indicating that the child resistant mechanism will not be effective

• Reduce customer complaints

• Designed for simplicity – Sophisticated technology engineered to minimize human error, easy GUI, simple user interface

• Non-interfering, non-degrading inspection – integrity analysis is done through the cap

• ROI – Cuts costs inherent in sampling methods, minimizes waste (time, work-backs, materials and labor)

• Reports enable statistical process control of the induction sealing process over time

• Brand integrity – Assurance that brand standards are upheld on the packaging line