| |

|

Achieve a

Perfect Seal

Induction Sealing Best Practices

|

Perfectly sealed products give consumers confidence in product quality and safety. Manufacturers know that poor seals not only threaten consumers’ perception of their companies and products, but also result in product spoilage and damage during shipment.

By understanding how to address and control induction sealing variables, companies can achieve a perfect seal every time.

The process of developing a perfect seal solution includes matching the cap, liner and sealer; setting up an operating window, and establishing testing methods for identifying a good seal.

Matching materials

Whether a closure (continuous thread cap, child resistant cap, or dispensing cap) is made from PET, PVC, PE, PP, PS, Gamma (multilayer), glass, Barex, PLA, or metal, a perfect seal can be achieved.

Choosing the right induction seal depends on the product being packaged. If the product contains any potentially aggressive or volatile ingredients, chemicals, acids, solvents, high salt content, alcohol or vinegar, a protective layer or barrier layer may needed. It can be sandwiched between the heat seal film and the foil to prevent corrosion.

|

|

Single piece liners often used in food and beverage industry. Image courtesy of Selig.

A two piece liner features two pieces of wax bonded material often used when packaging an aggressive or volatile product. Image courtesy of Selig.

The liner is the next consideration. One type is a single piece liner, which has a backing that is typically a board, foam or paper layer. When inducted, the entire structure seals to the container lip, leaving nothing in the closure for resealability.

This type of liner is commonly used in food, beverage, and vitamin applications or products that do not require a reseal liner in the closure after the foil is removed.

Another classification is a two-piece liner. This is a two-piece wax bonded material, which has a backing that is usually a board, pulp or foam bonded to the foil seal structure with a temporary wax bond. During the induction process the wax is heated, melted, and absorbed into the backing, which stays in the closure for resealability.

When packaging an aggressive or volatile product, a barrier layer may be included between the heat seal layer and the foil. |

|

Removal Characteristics- (L)Clean peel does not leave any residue.

(M) Welded seal’s must be destroyed to gain entry.

(R) Easy entry foil seals can be punctured with a finger. |

There is also a two-piece reseal that combines a high barrier retain liner with the induction foil. High polyester film is laminated on the backing to provide better oxygen permeation rates and moisture vapor transmission rates after the foil seal is removed.

Finally, the removal characteristics must be determined. Does the application require a clean peel where the entire liner peels away cleanly without leaving any residue? Does the productrequire a weld seal or tamper evident bond, where the foil must be destroyed to gain entry and leaving a residue on lip of container? Or, is an easy entry seal, where the membrane can be punctured with a finger or knife, desired?

Induction sealer

A number of variables need to be considered to select the right induction sealer for an application.

|

|

The foil diameter is one of the most important variables in sizing the equipment. A larger diameter of foil is requires a different amount of energy to seal than a smaller one. Since there are many types of foils and depending on their thicknesses, they can heat up differently, so it is essential to document the application’s foil type.

Knowing the line speed, preferably in feet-per-minute is critical. If the containers are traveling fast, the container will not be under the sealer as long, therefore a more powerful sealer will be required. If the only information available is containers per minute, the spacing between containers or pitch needs to be determined.

Cap and bottle geometries are additional considerations when selecting the optimal induction sealing head for the application. There are many different types of caps and bottles and |

Depending on the cap and container geometry different sealing heads may be required for optimal sealing efficiency. Picture above are common sealing head designs: (a)Tunnel sealing head, (b)Deep tunnel sealing head, (c)Flat sealing head, (d) Orginal All-in-one sealing head. |

|

Setting an operating window is key to achieving a perfect seal every time.

Application torque, air gap, sealer power output and line speed are the critical

variables to be assessed |

most can be sealed with a flat sealing head. However, some containers, such as those with sports caps, have a large gap between the top of the container and the induction liner that requires a special sealing head.

Additionally, the range of applications must be determined. If a wide range a containers or closures are to be sealed, the system needs to be sized for the complete range of cap/container/speed configurations.

Once all the information is documented, proper power supply and sealing head options can be chosen. For smaller diameter closures, a tunnel coil is typically the most efficient. For a sports cap or yorker type cap, a deep tunnel coil is most effective. For closures over 53 mm in diameter, a flat coil is the best solution. If the applicationincludes a wide variety of closure sizes, an all-in-one sealing head may be the best choice.

Operating window

Once the cap, liner, and induction sealing equipment have been selected, setting up an operating window for the induction sealer is the next step. An operating window enables the optimal sealing range to be determined by providing a record of sealing ranges that will provide no seal, a partial seal, a good seal, and an overheated seal. This information is very important because it provides the foundational baseline for each application.

Step 1: Ensure that the orientation and alignment of the sealing head are correct. The air gap between the sealing head and the closure must be consistent. It is also important to make sure that the bottle path is controlled and |

|

travels under the center of the sealing head or under a pivoted sealing head, based on manufacturer’s specifications.

Step 2: Check the variables including conveyor speed, which should be a fixed value for better result (if the operation requires sealing over variable conveyor speeds ask the induction sealer manufacturer about a Variable Sealing Control option). Ensure that closures and containers are compatible, examine containers and caps for defects, and verify consistent closure application torque. Over 80 percent of all sealing problems are related to torque issues.

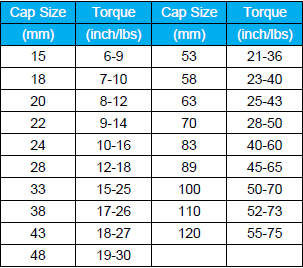

The chart above shows the industry standard torque requirements for successful induction sealing of various cap size.

Step 3: Determine the minimum set point. Start by setting the output percentage at a minimum level of the induction sealer, with all of the other variables fixed, run a single container through the |

sealer. Check the container for a seal. If no seal was achieved, increase output in five percent increments until there is a partial seal. Then, increase the output of the induction sealer inincrements of one to two percent until a complete seal is achieved; this is the minimum set point of the operating window.

Step 4: Set the maximum set point. From the minimum set point, increase the output of the induction sealer by five percent until the liner or cap shows signs of overheating. Then, decrease the output of the induction sealer by one to two percent until overheating is eliminated. Once that is established, the maximum set point of theoperating window is determined.

Step 5: Record the data. The output percentage that yields the best seal will be somewhere within the window of minimum maximum output set points. The variables that need to be recorded are the container details, the closure details, liner material details, closure application torque, conveyor speed, sealing head air gap, and the output of the induction sealer including minimum,maximum, and optimal set points within that range.

Determining a good seal

Although there are no industry standards for induction seal integrity, there are several ways to assess seal quality. Among the more effective methods are wet or dry vacuum testing, shipping the product to determine how it will respond, vision systems, mechanical pressure, and shaking, squeezing or standing on a sealed container. Characteristics of good seals that are visible to the naked eye include no discoloration of the liner, good adhesion around the entire circumference, |

|

A good seal exhibits adhesion around the circumference of the container, no discoloration and minimal wrinkling.

Excessive wrinkling, signs of burning or discoloration on either the liner or in the cap indicates that either the output is set too high or the line speed is too slow.

minimal wrinkling of the liner, and on two-piece liners, no darkening from overheating.

While many problems can be avoided by establishing quality control procedures on incoming caps and bottles, climate controlled storage, and FIFO inventory, it is beneficial to have a troubleshooting process based on the information provided in this article in order to expedite the identification and resolution of any induction sealing problems.

|

Induction Sealing Product Comparison |

|

|