Country

Thailand

Industry

Confectionery

Product apply on

Paper Box

Which label applicatoris being used?

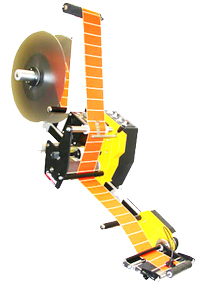

Collmat 7620

Labelling Speed

50m/min

Label Size

Diameter 42mm

Number of new Collamat units sold

1

Replaces

New application

Collamat 7620

• High variable speed enables

• High precision scaled adjustment

|

Background

Ezaki Glico Co., Ltd. was found in February 1922 by starting to produce confectionery in the form of camamel comprising of nutrient that is wholesome as glycogen under the name of "Glico", and started to launch in Mitsukoshi Department Store that was an old and famous department store in Osaka. Mr.Riichi Ezaki, founder of Ezaki Glico used glycogen extracted from fresh oysters inthe form of sugar compound like flour to go through the process to make confectionery. Although before theis he was successful in making and selling medicine and wine, but he was determined to produce confectionery with butrition to the body. So he stepped into the confectionery production tht he had never had experience before and dedicatd his whole life to the job by producing caramal confectionery under the name of "Glico". Mr.Rii spent 3 years to make his caramel confectionery "Glico" to enter market and several more years in expanding the market until it was well known in Japan. After that Ezaki Glico was unfortunately faced with the catastrophic crisis, his Glico factories in Tokyo and Osaka were destroyed during the Second World War entirely. However, from his endeavor and perserveance and hoesty and dedication by all his employees, including al lthe customers accepted and understood the value of his philosophy "Promotion of People’s Quality with a Precious Nutrient" enabled his company overcome the obstacles and crise. In 1980 Mr. Ezaki passed a way at the age of 97 years old, but his philosophy lived on, and Ezaki Glico still put on emphasis on promotion of quality for the consumers around the world with quality products.

Why we won?

Collamat® 7600 is with speeds up to 50 m/min the labelling machine for high production output. Adding the very highprecision of the unit makes it the preferred choice for advanced applications where speed and precision is a must. In addition comes easy handling, the modularity, simple integration, high reliability, all to very competitive costs, Perfect for a production with high output and high demands on labelling quality.

|