Country

Thailand

Industry

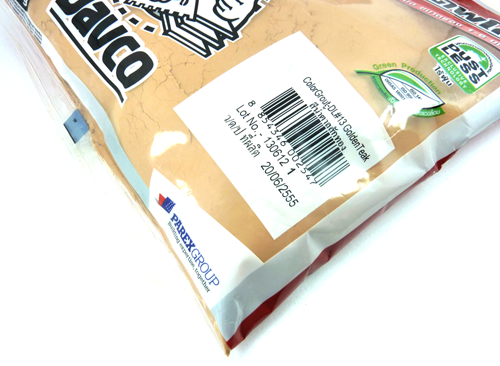

Chemicals / Tile adhesives and grouts

Product printed on

Plastic Film Contained

Which coder is being used?

Linx TT5

Throughput

45 bpm, 8 hours/day, 6 days/week

Messages content

Date, Text and Barcode

Number of new Linx units sold

2

Linx TT5 Printer

• Minimised production downtim

• Easy to use

• Low running costs

• Mimimum downtime-maximum reliability

|

Background

ParexGroup is a division of Materis, a leading provider of specialty chemicals for the construction industry.

Today, ParexGroup is one of the foremost producers of dry-mix mortars for the global building industry. We have 3100 employees in 20 countries, 54 manufacturing facilities, 9 research and development centers and have achieved 630 million Euros in sales in 2011. Our presence is strong in Western Europe, Asia Pacific, South and North America, North Africa and the Middle East.

We are going through rapid expansion despite the difficult economic environment. This is due to solid and selected positions in mature markets and our continuing success and rapid growth in emerging markets. High-growth emerging countries now account for 40% of our sales.

Why we won?

The customer is very successful and has plans to develop the plant. He wanted a coder that was at the cutting edge of technology and one that would keep pace with his expansion plans.

The Linx TT5 is designed to optimise productivity with its unique clutchless bidirectional ribbon drive, meaning minimal risk of ribbon breaks and no mechanical adjustments needed to maintain ribbon tension. Customers enjoy superb code quality as well as a significant increase in production line uptime and lower cost of ownership. The user interface allows users to preview messages before coding, reducing coding errors. It also has one of the longest standard ribbon lengths on the market (1000 metres) resulting in fewer ribbon changes.

|